ServiceDesk 4.4.76 Update 08/29/10

Further Improvements in the "To-Grave" Segment of our "Cradle-to-Grave" Parts Management System

Back with release of Ver. 4.3.99 (posted 8/31/08, you may peruse below to find), I thought I'd completing programming per the subject as described in this section's heading. As it turns, however, we've periodically learned of need for added improvements. This release introduces four more:

"To-Grave" Improvement #1. Among the "final disposition" checkoff categories we allowed for in Ver. 4.3.99 design, there was one called "RtrnCrdt" -- intended to show, alternatively, either that a part had been returned with expectation that you'd receive credit, or that return credit had actually been received (the choice of which way to use it was up to you). I should have realized at the time this was really a poor design. You need to be able to distinguish between the two modes. To that end, the "RtrnCrdt" choice has now been eliminated. In its place are two options: "RtToVndr" and "CrdtRcvd" (why couldn't I have been that smart from the start?).

Old DropdownNew Dropdown

You should note there is an important distinction between the old "RtrnCrdt" designator, and the pair of new ones. The old one was an in-the-grave categorization. So is one of the new designators ("CrdtRcvd"). The other ("RtToVndr"), however, is not. This latter is considered a still living-in-the-system, still in-process category.

FYI, any old records that have already been recorded with the old designator will stay as such, but from here on out you can use either of the much more descriptive pair (depending on which applies). For reporting/review purposes (see below), the system will treat the old designation as equivalent to "CrdtRcvd" (meaning, for those older items, it will still be up to you to verify via other means that credit was actually forthcoming).

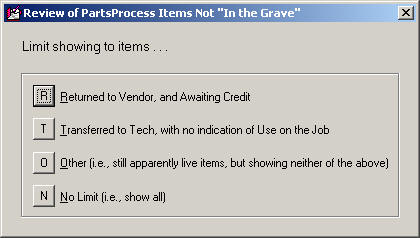

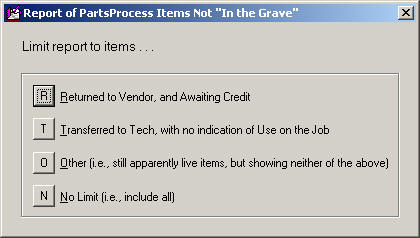

"To-Grave" Improvement #2. As part of the above-described Ver. 4.3.99 release, we introduced a new filter and new report in the archived-PartsProcess form (Ctrl-F8) -- a pair designed to let you review, for appropriate management, those particular s/o items that had been ordered and received, but had no entries indicating a final and proper disposition. As per original design, those showings were somewhat general in that they included all items not yet in the grave, without segregation as to category. With this release, segregation is now offered. Specifically, when you pick either of those options, you'll next see a dropdown that asks what sub-categorization you'd like.

This menu optionThis one

Leads to thisLeads to this

Thus (and as an example), if you want to specifically review items that have been returned to the vendor and on which you're awaiting credit, that specific category can be selected.

This brings up the point: to effectively harness the benefits as provided by Improvement #1 (described above), you should make it a practice, as you box up and send items back to your vendor for return credit, be sure to place them into the "RtToVndr" category. And, when you receive credit, be sure to go into the "RtToVndr" review category, eyeball the items on which you've received credit, and change their categorization to "CrdtRcvd"(this is the way to internally police, and truly assure the part is finally and fully "put to bed" every time, with credit having truly been received).

"To-Grave" Improvement #3. Recently a client pointed out that it would be very valuable to have a "Reverse PartsPickList." I was immediately and highly enamored of the concept. The notion is, it's a simple list (as provided to you on Tuesday morning, say) that shows everything that should be coming back from the tech, because not used from his work on Monday. Great -- I'd even say fantastic -- concept. I was immediately thinking, "Man, I want to make this ASAP!" But then, I thought, our "Parts Received But Not Disposed Of" report (above discussed) might actually (indeed, already) fulfill almost the same purpose. I pointed this out to the client, and he agreed that, yes, likely it would. However, he called back a short while later (having in the interim tried it), and indicated it really was not effective for the purpose -- by reason of the fact between techs that should have come back from the tech, versus others in the not-yet-in-grave category.

To redress that, besides the new sub-categorization described above, this release adds another: "In Tech's Possession" (see illustration above). It's not quite a Reverse PartsPickList, but (and for the time-being) it's a reasonably close facsimile.

Of course, there is the matter of how is the system to know that you actually (and physically) moved an item into the tech's possession? Until this release, there has been no formal designator of such fact built into ServiceDesk. However, many users have used the same BinLoc box (e.g., as used for designating "RtrnCrdt") for the purpose. More specifically, as they transfer a s/o part to a tech, they change that reference to his simple two-letter abbreviation. With this release, ServiceDesk will now recognize such a designator -- in particular, when applying the reporting/display filter that is the main subject of our "To-Grave Improvement #3."

FYI, as soon as I can do it, I'll create a new PartsPickList on-screen interface -- where you can simply click to indicate that items are being moved into the tech's possession, or back again. I'll also make a purpose-built Reverse-PartsPickList (as requested by that fine client) into an inherent part of it. Until then, you'll just have to do those changes manually.

"To-Grave" Improvement #4. This one, actually, goes beyond "to-the-grave" matters, but it was requested by another very clever client in the context of such concerns. He expressed the need for a method via which a tech can document why he ends up not using a part as prior ordered. My initial thinking is that such comments will likely go into the underlying Request-Item's Notes section.

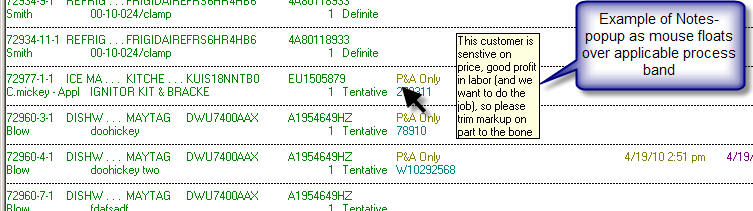

Thinking about that particular Note section's use (for this added purpose), brought to mind two complaints users have made in its regard. To clarify, I'm referring to the large Notes section as found in the underlying Request (Alt-F8 form), not the smaller Notes section as found within a Process-Item (F8) band. One complaint has been that, when you're in the PartsProcess area, that larger section (which may have info you really need to know about) is not readily or automatically visible (you have to right-click in the Reference section to bring up its containing/underlying request). Another is that, once the Request item is archived (Ctrl-F8 form), those larger notes are no longer available at all.

This release address both matters. Regardless of whether you're in the Current- or Archived-PartsProcess forms, ServiceDesk will now display any underlying Request-Notes, in a ToolTip-type fashion, as your mouse floats over a process-band to which such notes are applicable.

Provision for the tech to document why he did not use an ordered part will be made in SD-Mobile (watch for updates there, along with mechanisms for such info to also auto-insert into these now much more available Notes.

Improved Item Selection When Printing Inventory Parts Labels:

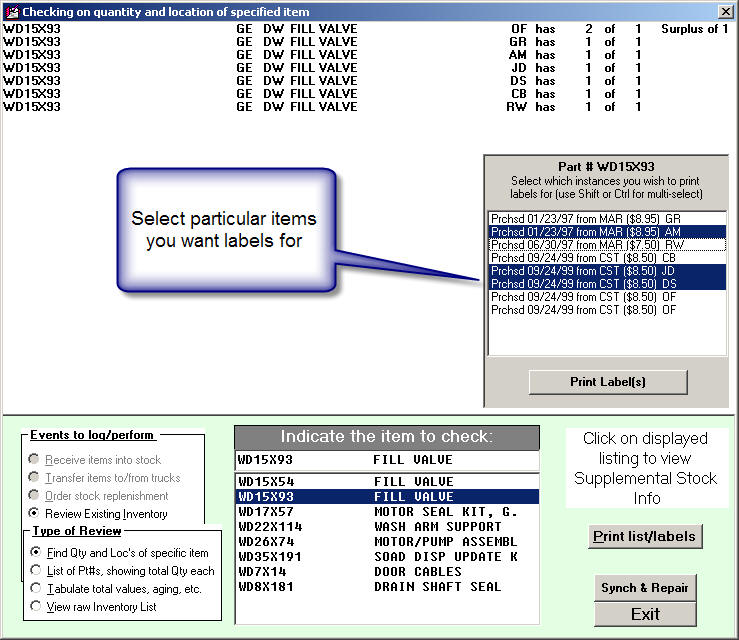

When you're checking a shipment of new inventory via the F10 form, the dialog asks if you want to print labels for the items checked in. As a rule, it's best to do the printing at this point, because we've lacked a means to specify specific/particular items for label-printing thereafter. To clarify, you've been perfectly able -- after the fact -- to print labels for all of the parts in a given location, or all of a particular part number. You could even print one label as pertaining to a particular number, but with no ability to specify which instance (of multiples you might have in stock) that particular printout would pertain to.

This release solves that. Specifically, when you choose to print labels as pertaining to a particular part number (from the F10 form use the option sequence "Review existing inventory" and "Find qty and locs of specific item," pick an item, then click on the "Print list/labels" button), you'll get a list showing each instance.

Just pick the particular listings you want labels for. To select multiple items, user the standard Windows multi-select tricks (i.e, use Shift-Click on other item to select a range, Ctrl-Click to include or exclude an added item individually).

Font Color and Other Options Added to the Up-Front Ticket-Printing Setup

These days technology moves fast, and we'll admit that even here at Rossware we are somewhat surprised to have so soon reached the point where -- viewing you guys out there -- we see printing tickets for service (at least prospectively from the office) as a bit quaint and old-fashioned. Most modern, we feel, is to have no paper tickets at all, and instead E-Tickets are provided to the customer via Mobile (a shameless plug here for that product). A large number of users have migrated to this model, and, if you have not, we encourage you to do so.

Regardless, we're not yet ready to stop injecting improvements into such tried and true methods as printing a beautiful ticket in the office, and sending the tech out with it. For a comparison, eye glasses are now a very old technology. But if you're going to use eye glasses, certainly you want the best that current technology can deliver.

Recently a user pointed out that it would be useful if he could specify particular colors for particular items of text within the up-front ticket. It seemed to make a lot of sense. Current updates in both ServiceDesk and the SD-Tools utility allow you to do this (both will need updated, the latter to Ver. 4.3.7; it's part of the SD-Update download unzip, but unlike ServiceDesk itself will not automatically copy from station to station). Additionally, you can now specify FontUnderline and FontStrikeThrough as characteristics. Just use SD-Tools for such setup, as per standard. Of course (we should not need to say this, but you'd be surprised), you'll need to use a color printer to make it work.